Robots & Cobots

Welcome to the forefront of automation, where innovation and collaboration converge to shape the future. Explore a spectrum of cutting-edge solutions, from the precision of robots to the harmonious partnership of cobots. We showcase technology’s transformative role in reshaping industries, production, and manufacturing processes, offering a dynamic world where technology meets human expertise.

Welcome to the world of Cobotics, where collaboration meets automation to redefine the future of manufacturing. At Pi Automations, we introduce you to the innovative and exciting realm of collaborative robots, or “cobots,” designed to work seamlessly alongside human operators, revolutionizing the way we perceive automation.

What are Cobots

Collaborative robots, or cobots, are a new breed of intelligent machines that are breaking barriers in industrial automation. Unlike traditional robots, which often require safety cages and isolation from human workers, cobots are designed to collaborate directly with humans in shared workspaces. With advanced sensors and cutting-edge safety features, cobots can operate safely alongside their human counterparts, opening up a world of possibilities for automation in various industries.

Unleashing the Potential of Cobots

Cobots are redefining automation, unlocking a multitude of applications across diverse industries. Their flexibility, adaptability, and user-friendly interfaces make them the perfect companions for a wide range of tasks, allowing manufacturers to achieve unprecedented levels of efficiency, productivity, and innovation.

Assembly Line Assistance

Cobots excel in repetitive and intricate assembly tasks, collaborating with human workers to accelerate production rates and ensure flawless product assembly.

Material Handling

From lifting heavy loads to transporting materials, cobots streamline material handling processes, reducing the strain on human operators and enhancing productivity.

Quality Inspection

Cobots equipped with advanced vision systems can perform precise and consistent quality inspections, identifying defects with unmatched accuracy.

Welding and Joining

Collaborative robots assist in welding and joining operations, ensuring consistent welds and freeing skilled welders for more complex tasks.

Pick and Place

Cobots efficiently pick, place, and sort items in various manufacturing scenarios, simplifying logistics and optimizing production flow.

Machine Tending

Cobots expertly tend to CNC machines and other automated equipment, increasing uptime and minimizing manual intervention

Packaging and Palletizing

Cobots handle packaging and palletizing tasks with dexterity, reducing manual labor and enhancing packaging efficiency.

Food and Beverage Industry

Cobots are ideal for food handling and preparation, guaranteeing hygiene standards while improving food production processes.

The Extraordinary Pi Cobot Bartender ”ΠarBot”

At Pi Automations, we’ve harnessed the immense flexibility of cobotics to create something truly remarkable – the Pi Cobot Bartender “ΠarBot”. This delightful cobot can be programmed to mix and serve cocktails with precision and flair, captivating audiences at events, exhibitions, and even in your very own establishment. With its impeccable bartending skills and interactive charm, the Pi Cobot Bartender demonstrates the limitless potential of cobots to entertain and engage.

Experience the Future with Cobots

With cobotics, the future of automation is collaborative, adaptive, and extraordinary. These remarkable machines empower your workforce, driving productivity and efficiency to new heights. From simplifying mundane tasks to creating captivating experiences like the Pi Cobot Bartender, cobots are the epitome of technological ingenuity and human collaboration.

Unlock the endless possibilities of cobotics with Pi Automations. Contact us today to explore how cobots can revolutionize your manufacturing processes and create truly remarkable automation experiences.

Experience the Future with Robotics

With robots, the future of manufacturing is driven by precision, speed, and adaptability. These intelligent machines optimize workflows, reduce human labor, and create a safer work environment. From revolutionizing assembly lines to streamlining logistics, robots represent the epitome of industrial innovation and efficiency.

Unlock the transformative potential of robots with Pi Automations. Contact us today to explore how robotics can elevate your manufacturing processes and drive your business towards unparalleled success.

Transforming Manufacturing with Precision and Versatility

Welcome to the world of Robotics, where cutting-edge technology converges with industrial prowess to redefine manufacturing. At Pi Automations, we introduce you to the transformative power of robots, designed to optimize production processes, boost efficiency, and elevate your manufacturing capabilities.

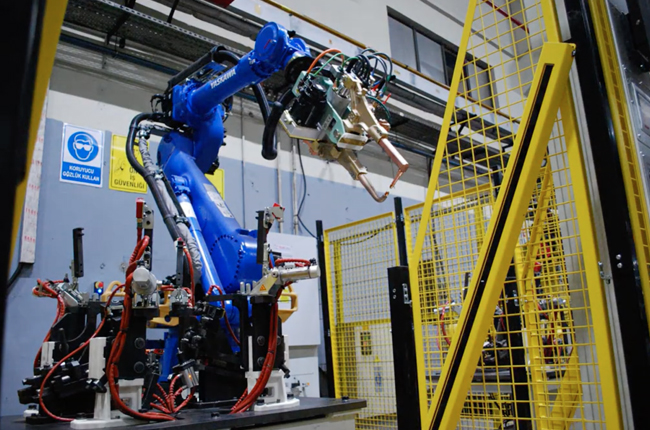

What are Robots

Robots are sophisticated machines programmed to perform various tasks with precision, consistency, and efficiency. Equipped with advanced sensors, intuitive interfaces, and powerful actuators, robots are revolutionizing the way we approach automation in the manufacturing industry.

Unleashing the Potential of Robots

From assembly lines to material handling, robots offer unrivaled versatility and adaptability, making them invaluable assets in numerous applications across diverse industries. Their ability to tackle repetitive tasks and handle complex operations with ease makes them essential partners in the quest for streamlined and efficient production.

Assembly Line Automation

Material Handling and Logistics

Welding and Joining

Robotic welding systems ensure precise and uniform welds, boosting welding speed and freeing skilled welders for more complex tasks.

Painting and Coating

Quality Inspection:

Equipped with advanced vision systems, robots conduct thorough quality inspections, identifying defects with unmatched accuracy.

Machine Tending

1.Robots expertly tend to CNC machines and automated equipment, enhancing productivity and minimizing manual intervention.

Pick and Place Operations

Robots handle pick and place tasks, precisely transferring objects in manufacturing, packaging, and logistics applications.

Palletizing and Packaging

1.Robots efficiently palletize and package products, streamlining packaging processes and optimizing warehouse operations.

Cleanroom Operations

Robots maintain cleanroom environments, reducing human contamination risks and ensuring consistent quality in sensitive industries like electronics and pharmaceuticals.

Soldering and Electronic Assembly

Robots are capable of delicate soldering and electronic assembly, ensuring precise connections and efficient production in the electronics industry.

Experience the Future with Robotics

With robots, the future of manufacturing is driven by precision, speed, and adaptability. These intelligent machines optimize workflows, reduce human labor, and create a safer work environment. From revolutionizing assembly lines to streamlining logistics, robots represent the epitome of industrial innovation and efficiency.

Unlock the transformative potential of robots with Pi Automations. Contact us today to explore how robotics can elevate your manufacturing processes and drive your business towards unparalleled success.